We can also handle orders for small lots and order with tight deadlines |

Our company has a full range of facilities and equipment available for molding of everything from small scale products to large scale products.

We will carry out the entire process from mixing design to prototyping, testing, inspection, mass product, quality management and shipping management all in-house so we can flexibly respond to customer requirements such as "we want to lower inventory costs, but also want the products right away".

|

|

|

[ Case example ] Solar panel manufacturer |

We received a consultation on large scale rubber sheets used in manufacturing equipment for solar panels.

・ Existing large scale sheets were made by adhering multiple sheets together.

・ Because the sheets are adhered together, the strength of the bonded parts will be weak and problems can occur. |

|

| |

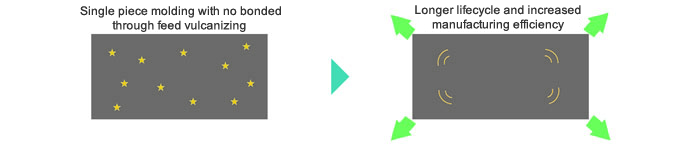

Can a large scale sheet be made with no bonded sections (with less reduction in strength)? |

We proposed using a "feed machining technique" where vulcanizing is carried out while feeding the sheet

For normal press vulcanizing, the pressurized press is not reapplied however there is no equipment capable of making the large scale sheet.

Our company managed to use our original compounding and preparation methods, vulcanization temperature, pressure, vulcanization time and die design to create a large scale sheet without bonded sections. |

|

| |

Width 2,600mm x Length 5,300mm |

|

|

The above example is only one small sample of our past successes.

Our company has managed to satisfy a wide variety of customer requirements, including examples such as 2 color molding and hollow molding, using the experience and technology we have cultivated up until now based on our past proven successes. |