|

Showa’s technology |

We wanted a rubber with these properties, but weren't sure how to go about formulating it… |

| We develop optimal formulations of customized mixed rubbers and provide them in rolls or sheets, with color, quantity, size and other factors all based on customer requirements. |

|

|

Can this be made of rubber? |

We propose, develop and provide products which suit customer needs.

The specifications required by customers vary greatly according to usage environment and conditions.

These specifications can be very diverse: soft, hard, high strength, abrasive resistant, oil resistant, chemical resistant, sanitary, transparent, hollow, composite, etc.

The combination of our engineers, who have an intimate familiarity with the rubber related technology, knowhow, and experience cultivated by Showa Rubber over 100 years, the fusion of these with current new technologies and our replete test processing, measurement, analysis and other equipment allow us to capably respond to customer demands. |

|

|

|

Development flow |

|

We check specifications, requirements, capacity, etc. |

|

|

|

Our engineering staff, who are familiar with every aspect of raw material rubber selection, compounding agent selection, vulcanization temperature, times, die designs, processing machinery selection and all other relevant fields, are put in charge of testing in order to satisfy customer requirements. |

|

|

|

Specialist staff check that specifications and required performance are fulfilled. |

|

|

|

We provide customers with prototype samples and testing data. |

|

|

Mass production flow |

|

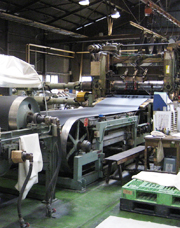

The Refining Department carries out compounding, rolling and sheeting on equipment suited to customer needs (quantity, color, size, etc.). |

|

|

|

The Inspection Department carries out checks of the rolled rubber vulcanization and physical properties, etc. |

|

|

|

Vulcanization is carried out using the vulcanization press and adequate temperature, time and molding pressure (for the press) specified in the standards. |

|

|

|

The Inspection Department carries out rigid testing in accordance with inspection overviews which are carried out with the customer and then issue an inspection results form for products which pass inspection. |

|

|

|

Products are shipped so that they will be delivered by the customer's desired delivery date. |

|

|

Please contact us if you have any issues or questions. |

We provide a one-stop system that can handle everything from compounding design to testing, mass production and management inspections.

Contact us with any of your rubber issues. |

|